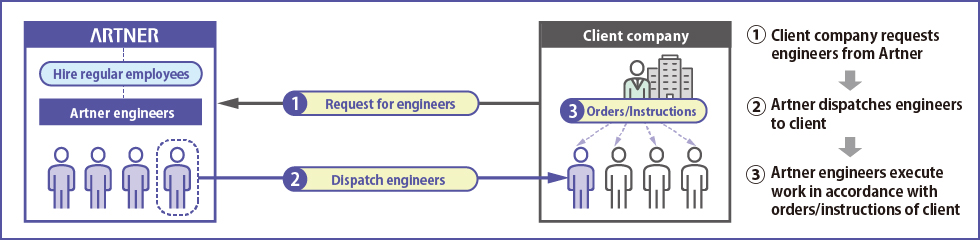

Artner concludes full-time employee contracts with engineers, and our corporate clients (dispatch destination) and Artner engineers are connected under a chain of command system. By not assuming the role of direct employers, our corporate clients can achieve substantial savings in terms of time and costs related to employment.

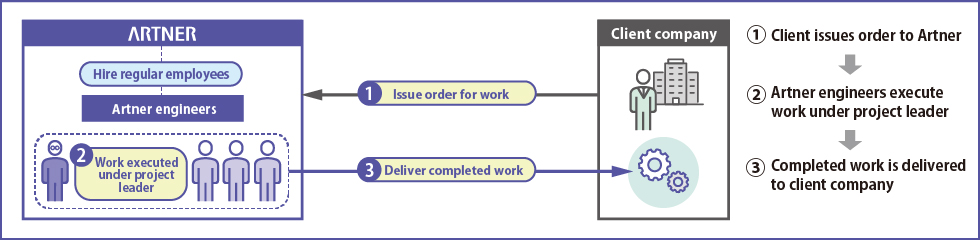

This business handles everything from orders for design and development work to delivery. It takes on orders for actual work and can respond to various requests of corporate clients from design and development work to design and engineering work.

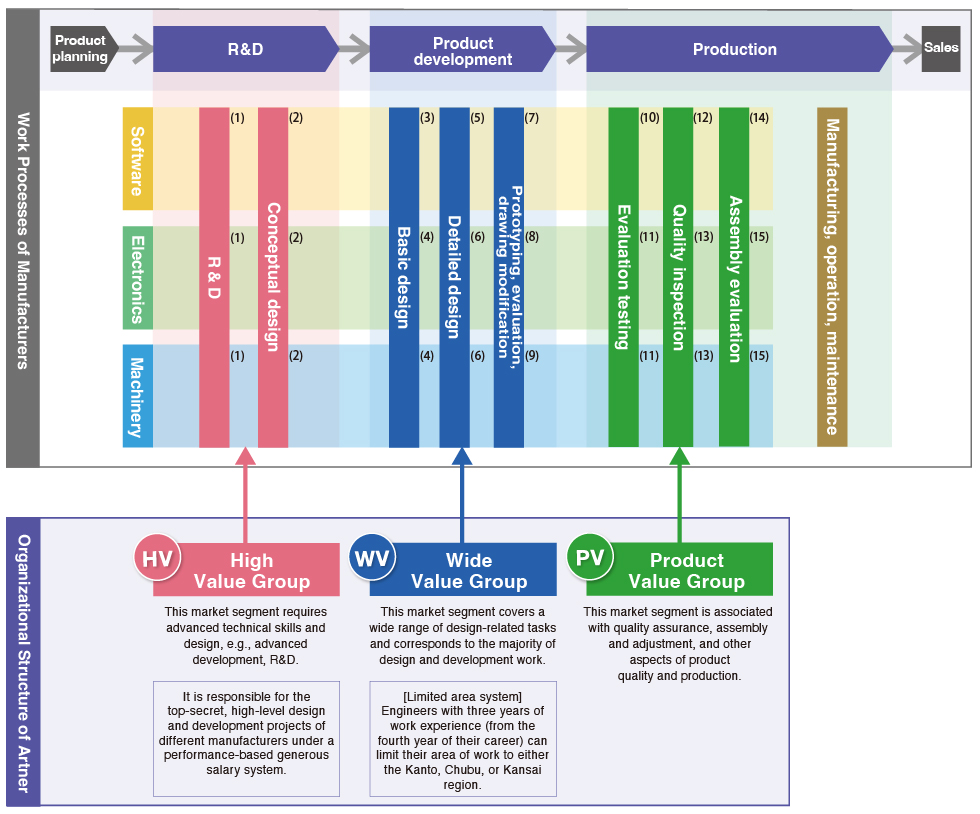

In manufacturing, there are various processes: product planning, design and development, quality control, and production. Other branches of work include sales, which sells the products, and general affairs, which supports the organization. Artner’s engineers can work in fields that make up the core of the work processes of manufacturers, such as R&D and product development.

【Detailed processes】

(1) Advanced development of an upcoming product, including market research

(2) Development of core technologies, development of new functions, preparing specifications

(3) Requirements analysis, functional design

(4) Product design for mass production, functional testing

(5) Detailed design, coding, design and improvement of additional functions, modeling, simulation, code generation

(6) Production facility design and maintenance, production tool design, drafting, performance evaluation

(7) Unit/integration testing, log data analysis, failure analysis

(8) Revision of the schematic diagram/parts list, operational checks

(9) Drawing revisions, failure analysis, operational checks

(10) Reliability testing, test result and log data organization

(11) Product quality assurance testing, standards-based testing

(12) Quality control, operational maintenance

(13) Production plan development and coordination, parts procurement, quality assurance

(14) System testing, pre-shipment inspection, kitting

(15) Product manufacturing and assembly, quality checks