Ever since a design firm was started by our founder, we have made continual changes in our mindset to cater to the evolving trends of the times, eventually developing our current business model as a technical service provider and creating value for engineers.

Value Creation Process[PDF 1.23MB/1 page]

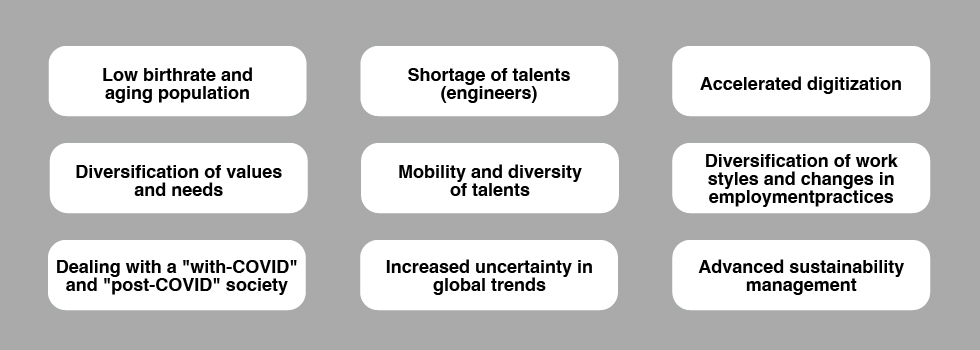

External environment and social issues

Inputs

Sources of Value Creation

The Company has grown by staying attuned to societal changes and needs and contributing to solving social issues. In the course of this, we have accumulated various capital that is the sources of our current strengths. We will seek to strategically utilize and increase this capital and pursue further value creation.

Solid and strong financial base supporting

sustainable growth

Equity ratio

Net assets

Cash flows from

operating activities

69.9%

42.7billion yen

11.2billion yen

Practical education and training by

training managers with engineer backgrounds,

based on training curricula aligned with clients’ work

Percentage of training

managers with

engineer backgrounds

Average hours of annual

training per

employee (engineer)

Average cost of annual

training per

employee (engineer)

Regular employment of engineers with

STEM backgrounds who can be placed in

upstream/midstream work processes of manufacturers

Number of engineers

Percentage of

engineers with

STEM backgrounds

Engineers who can be

placed in upstream/

midstream work processes

of manufacturers

Long-term partnerships with clients, schools,

academic societies, and organizations

Transaction history

Schools from which we hired (graduate, undergraduate,

junior college, technical, and professional schools)

Roughly1,200 companies

Roughly 350 schools

Papers published

Part-time lecturing at universities by

our training managers

166

15 courses at 8 schools

Business Activities

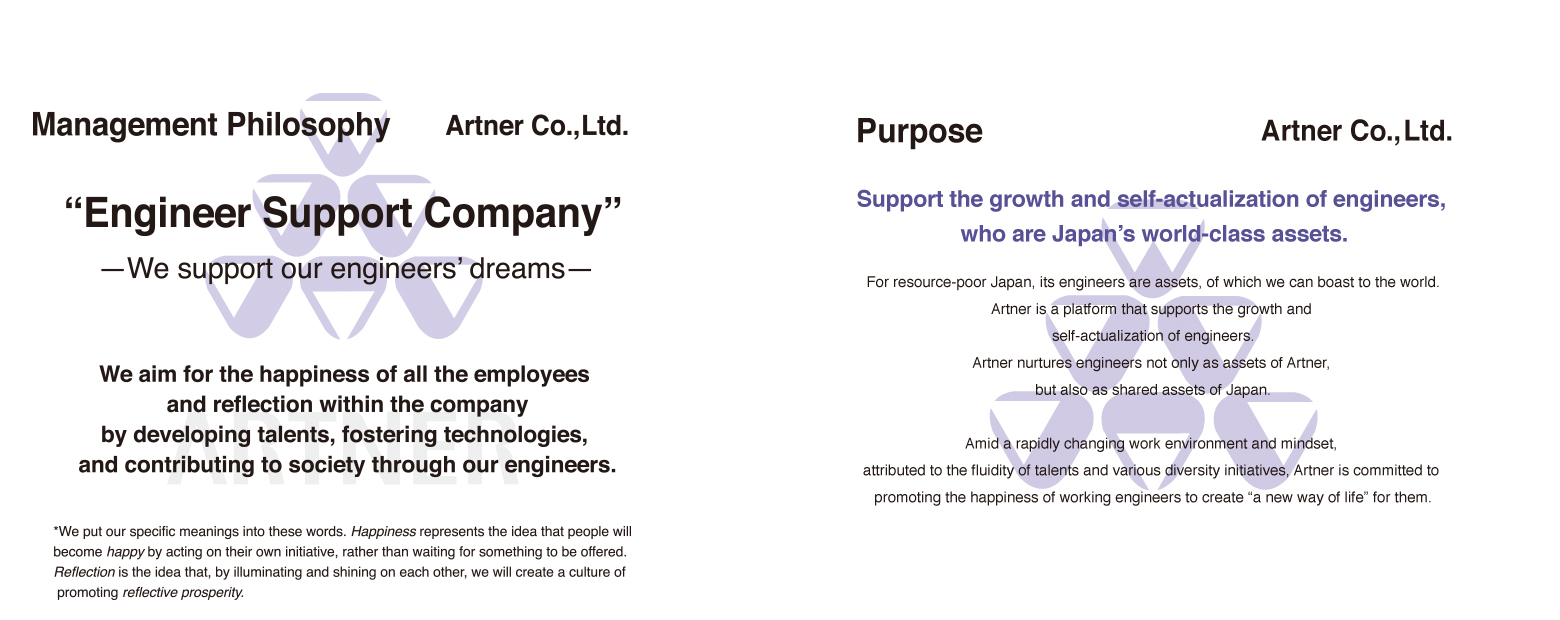

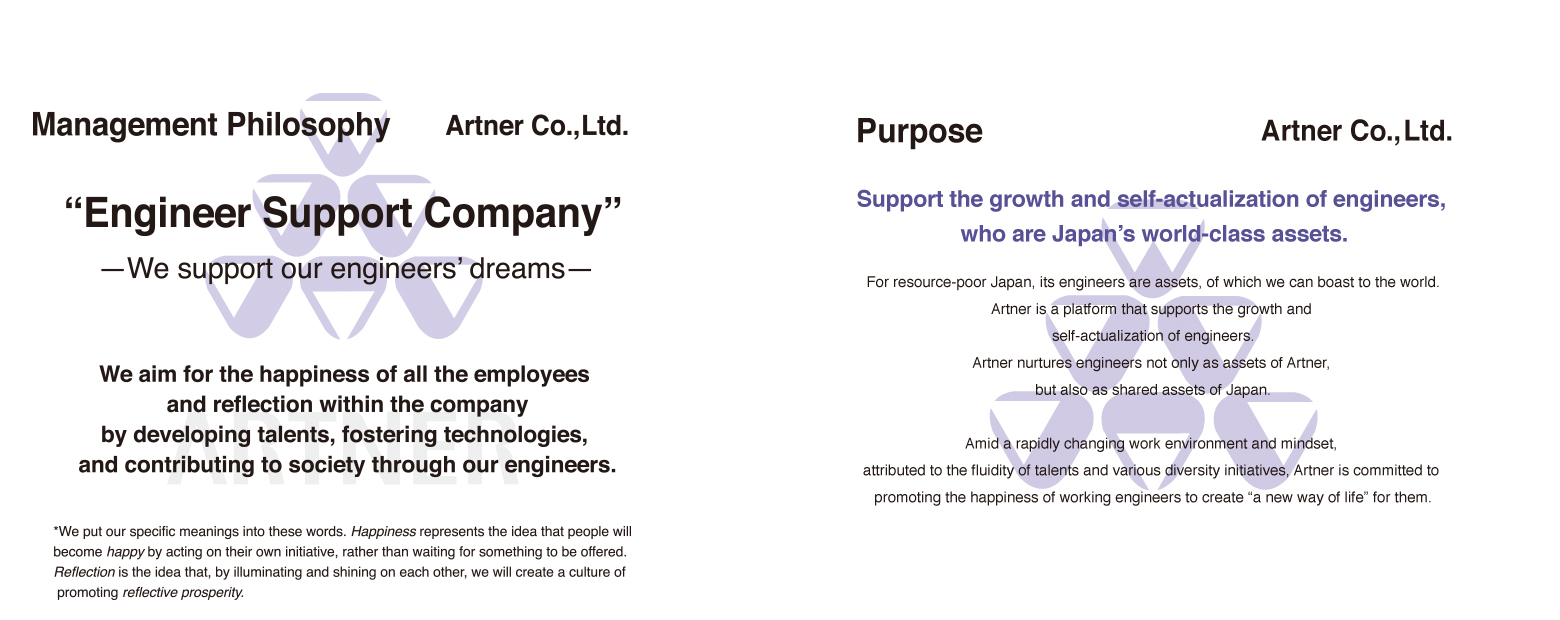

Management philosophy/Purpose

Our strengths

1.Trust from our clients built on our long history

Founded in 1962 as a design and development firm, the Company grew by

winning contract work for design and development from manufacturers in the

Keihanshin region, which drove Japan’s rapid economic growth. In our nearly

60-year history, we have succeeded in building trust with many client companies

and accumulating a proven track record as a group of engineers with roots

in design and development.

2.The business model we have developed

over many years

Even during the global financial crisis of 2008, not many engineers who were

placed in the upstream work processes of manufacturers (R&D) experienced

contract cancellations. As such, we decided to increase our engineers’

upstream assignment ratio. To help us recruit excellent students who may be

suited for upstream assignments, we have introduced internal programs based

on the needs of engineers (e.g., job change assistance program,

performance-based salary system, and limited area system).

3.Placement of engineers in technical fields with

high market needs

Our engineers’ business fields are wide-ranging. At major companies in the

automobile, home electronics, industrial equipment, medical device, and

information and communications sectors, engineers participate in and provide

a variety of technical services for cutting-edge projects, including eco cars

such as electric vehicles (EVs) and fuel cell vehicles (FCVs), driver assistance

technologies, racing cars, semiconductor lithography equipment, industrial

robots, and system and application development.

4.Job-based employment that allows career

development within the Company

We employ talent with STEM backgrounds as regular employees in technical jobs

and offer an environment where they can focus on honing their skills as engineers.

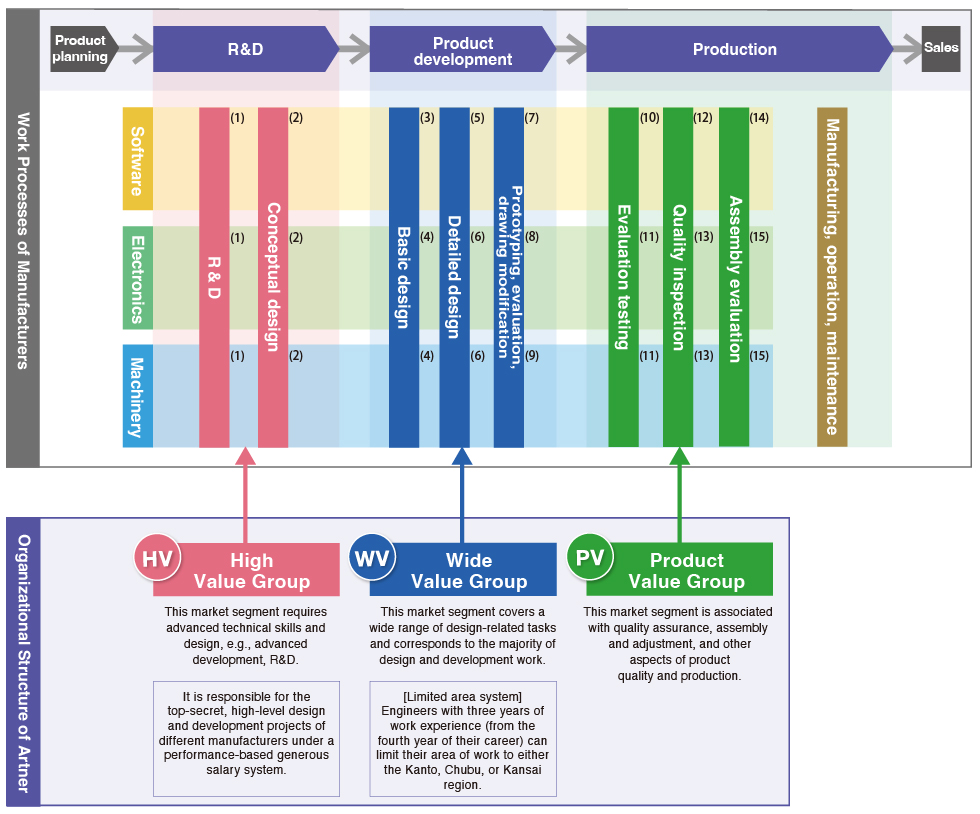

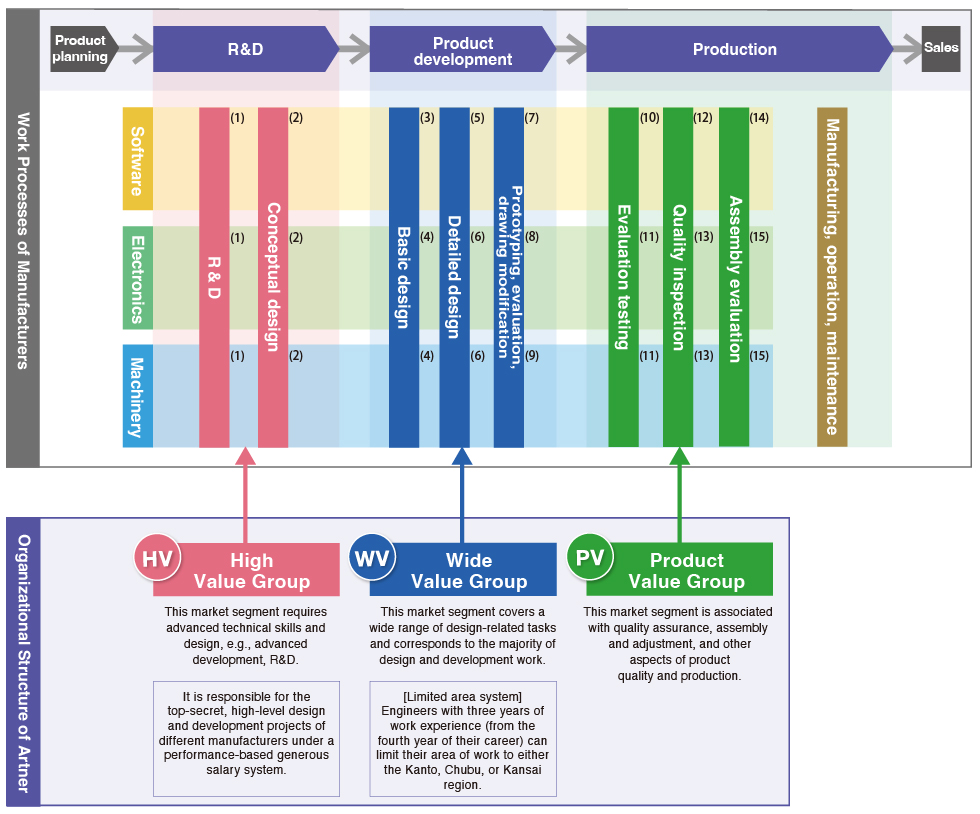

We classify the work processes of our clients into three categories: R&D;

product development; and production. Correspondingly, we have established three

groups for each area (High Value Group, Wide Value Group, and Product Value

Group). Engineers can move between these groups according to their preferences

and competence and develop their careers within the Company.

Our business and technology domains

【Services provided for work processes of manufacturers】

【Detailed processes】

(1) Advanced development of an upcoming product, including market research

(2) Development of core technologies, development of new functions, preparing specifications

(3) Requirements analysis, functional design

(4) Product design for mass production, functional testing

(5) Detailed design, coding, design and improvement of additional functions, modeling, simulation, code generation

(6) Production facility design and maintenance, production tool design, drafting, performance evaluation

(7) Unit/integration testing, log data analysis, failure analysis

(8) Revision of the schematic diagram/parts list, operational checks

(9) Drawing revisions, failure analysis, operational checks

(10) Reliability testing, test result and log data organization

(11) Product quality assurance testing, standards-based testing

(12) Quality control, operational maintenance

(13) Production plan development and coordination, parts procurement, quality assurance

(14) System testing, pre-shipment inspection, kitting

(15) Product manufacturing and assembly, quality checks

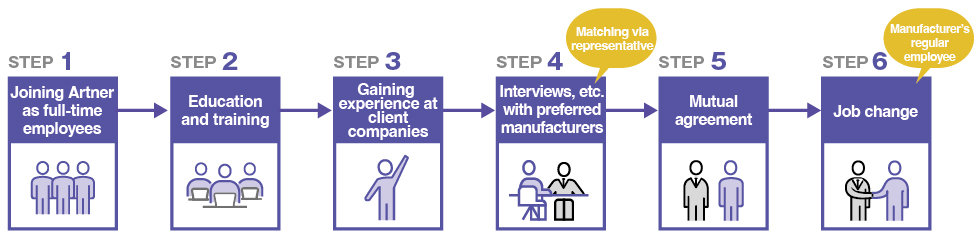

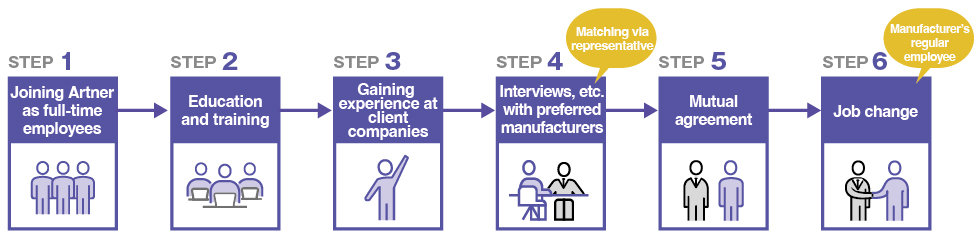

【Job change assistance program】

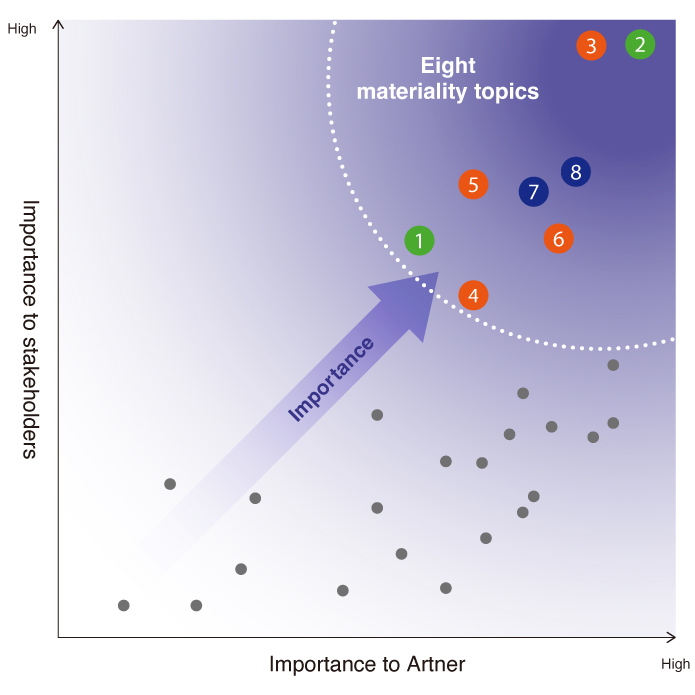

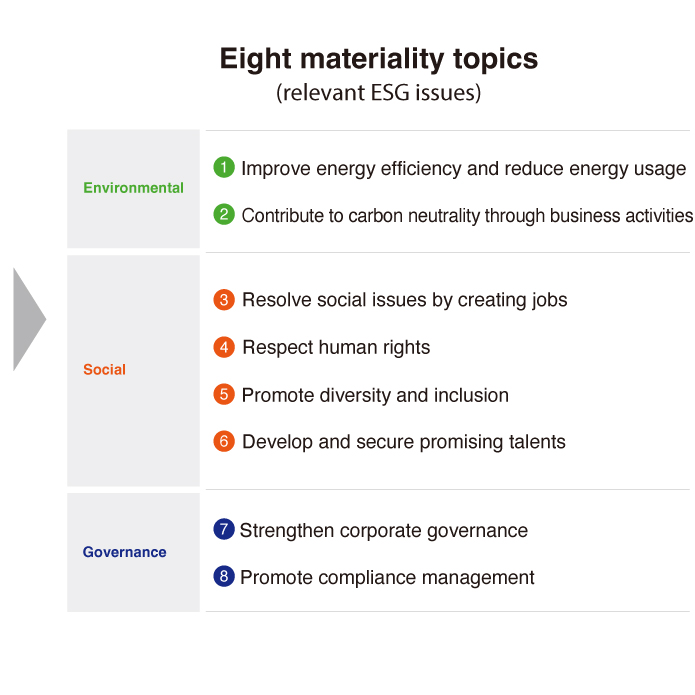

Eight materiality topics

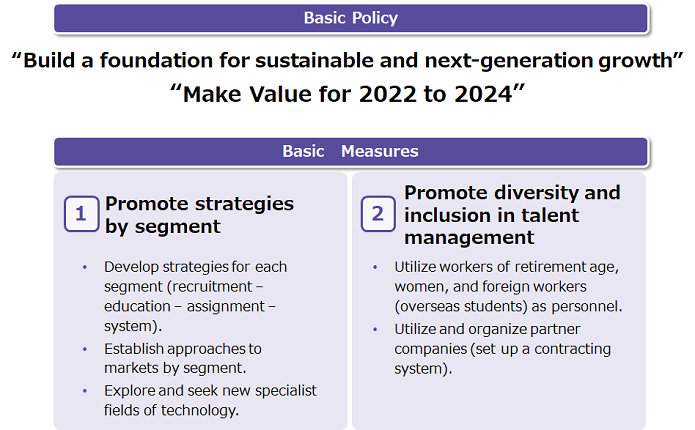

Medium-Term Business Plan

Outcomes

Values provided

* We put our specific meanings into these words. Happiness represents the idea that people will become happy by acting on their own initiative, rather than waiting for something to be offered. Reflection is the idea that, by illuminating and shining on each other, we will create a culture of promoting reflective prosperity.

* We put our specific meanings into these words. Happiness represents the idea that people will become happy by acting on their own initiative, rather than waiting for something to be offered. Reflection is the idea that, by illuminating and shining on each other, we will create a culture of promoting reflective prosperity.

Medium- to long-term goals