Mechanical engineers design the mechanisms of machines with moving parts using 2D/3D CAD tools.

Design areas include Drive Systems (development of mechanisms for generating, converting, storing, and transmitting energy), Mechanisms (development of mechanisms for production facilities and equipment), and Structures and Materials (design of products in various formats, formulation of structures and housings, and development of new materials).

To perform our engineering work, knowledge of the four major dynamics (dynamics of machinery, strength of materials, fluid dynamics, and thermodynamics) is required.

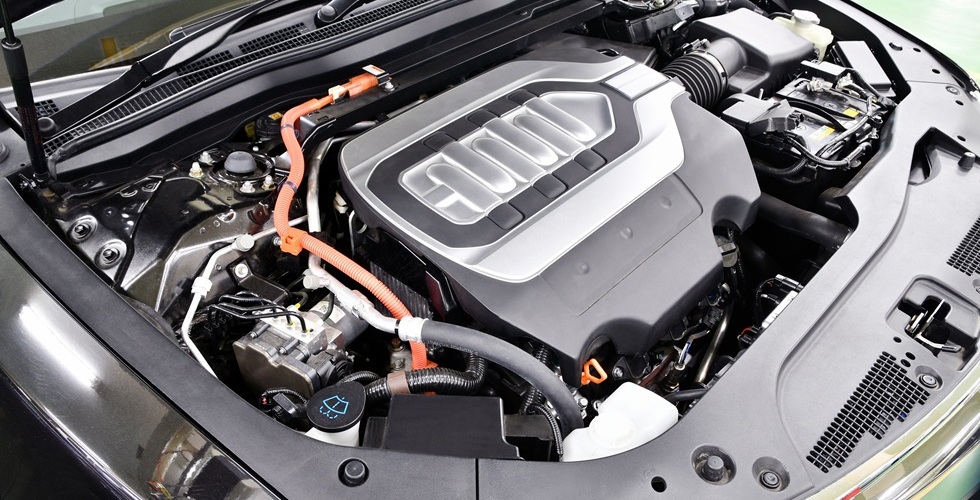

•Structural design of fuel cell units, as well as any ancillary work

•Structural development of fuel cells/EVs, as well as any ancillary work

•Structural development of powertrains, transmissions, etc., as well as any ancillary work

•Structural development of various motors, as well as any ancillary work

•In addition to knowledge of mechanical design, basic knowledge of electrical circuits for the development of fuel cells.

•Knowledge of metal materials (magnetic and non-magnetic) and resin materials.

•Knowledge of shaping various parts for the structural development of fuel cells/EVs.

•Knowledge of thermodynamics and thermal/fluid analysis if peripheral part development for fuel cells is involved.

•Comprehension of the structures of various parts for the structural development of powertrains, transmissions, etc.

•Knowledge of structural design, the strength of materials, and stress analysis.

•Knowledge of mechanical design, basic knowledge of electrical circuits, and knowledge of metal materials (magnetic and non-magnetic) for the structural development of motors.

•Since motors generate noise and vibrations when driven, knowledge concerning noise and vibrations.

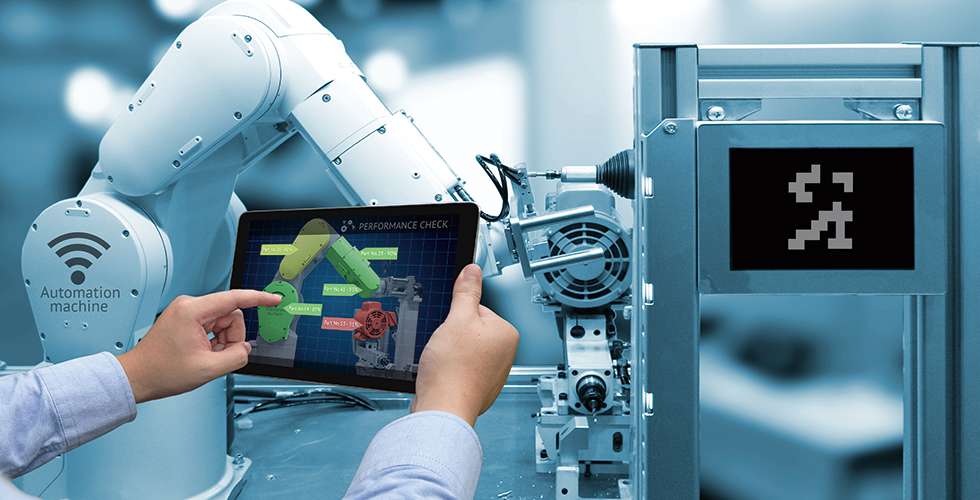

•Development of production equipment and devices, such as semiconductor manufacturing equipment and etching systems

•Development of robots, mechatronic equipment, and pneumatic equipment

•Development of mechanisms for scientific equipment, printers, inspection equipment, etc.

•Development of production technologies and methods for production lines, and process management thereof

•Development of manufacturing equipment and jigs for manufacturing

•Since many parts that comprise mechanisms have relatively complex shapes, the ability to create drawings that incorporate surface qualities, geometric tolerances, welded structures, etc.

•Knowledge concerning mechanical materials (mainly iron and steel) that comprise devices.

•Knowledge of the mechanical components that comprise devices and mechanisms, mechanical components for transmission, hydraulic and pneumatic equipment, instrumentation parts, and control equipment.

•Since design calculations, such as those for part curvatures and inertial forces, are essential, basic knowledge of the strength of materials and dynamics of machinery.

•Since opportunities to observe assemblies and device installations will arise if promoted to senior positions, basic knowledge of the key points of assembly and adjustment.

•Development of structures for design-based products, such as non-driving parts (bodies, exteriors, interiors, and harnesses) for transportation equipment and enclosures for medical devices, home appliances, aircraft, etc.

•Development of new materials, such as electrode and metal materials

•Development of mass production processes, such as resin molding and casting

•Since it is necessary to design transportation equipment, home appliances, etc. that fall under the scope of work with the assumption that they will be mass-produced, the ability to create drawings that incorporate knowledge concerning processing methods.

•Since strength is required across a wide range of environments from low to high temperatures, basic knowledge of the strength of materials, thermodynamics, fluid dynamics, etc.

•Since mastery of various materials, such as resin, metal, and polymer materials, is necessary to fulfill product functionalities, knowledge concerning materials.

•Since processing large amounts of numerical data, such as material combinations and verification results, is required for the development of new materials, basic knowledge concerning data processing.

Artner’s mechanical engineers have a proven track record in a wide variety of projects in the core areas of manufacturers’ business processes.

●Development of eco car chargers

●Development of drive motors

●R&D related to next-generation HV batteries

●In-vehicle testing and evaluation of HV transmissions

●Measurement, analysis, control, and evaluation of LCD lithography equipment

●Driving test and analysis

●Development in the engine domain

●Design and development of chassis, suspension, and underbody components

●Design of circuits for automobile meters and HUDs

●Design of wire harness circuits

●ECU evaluation and prototyping

●Detailed design of onboard satellite equipment

●Aircraft strength analysis

● Prototyping, evaluation, and analysis of smartphone circuit boards

●Development of AV equipment

●R&D of high-performance catheters

●Improvement of blood transfusion and infusion sets, design of next set

●Vehicle testing in motorcycle R&D

●Design and development of motorcycle clutches

●Design of hygiene product manufacturing equipment

●Design and development of mechanisms for production facilities

At our extensive in-house training facilities, new mechanical engineers receive two levels of specialized training: basic training and customized training (practical training).

The trainees will be retrained from scratch, reviewing what they learned in school.

This practical training curriculum involves focusing on how to apply the knowledge learned in school to actual development work.

This training focuses on specific client company operations to provide process-based education that matches the needs of each workplace. The trainees will acquire a wide range of necessary technical skills, from basic to application.

Training curriculum